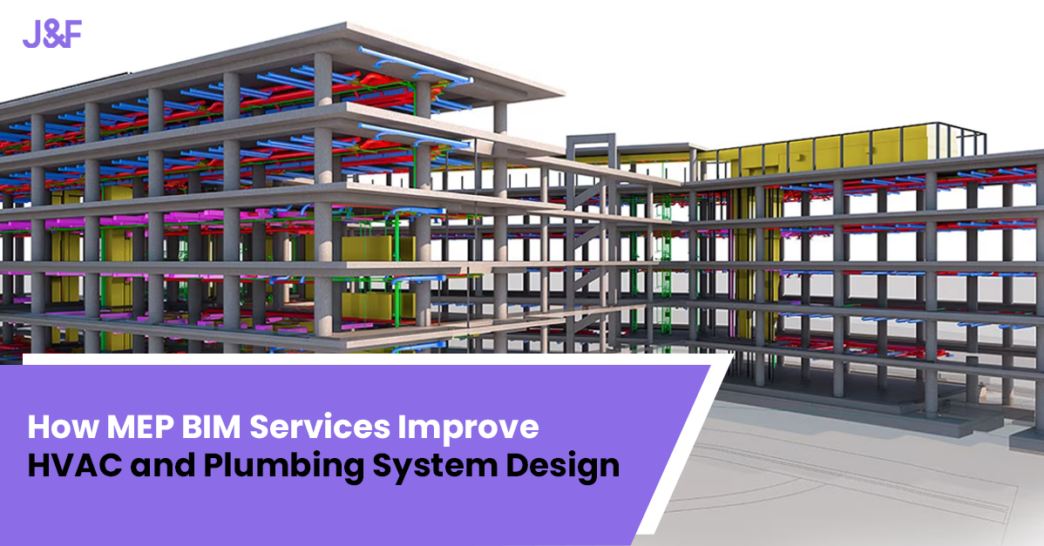

HVAC and plumbing systems are the backbone of every project. The way they are conceptualized and installed significantly influences the project quality. Whereas HVAC, which stands for Heating, Ventilation, and Air Conditioning, controls indoor climate and air circulation, plumbing systems cater to water supply and wastewater management. The reliability and installation of either system should be on point, adhering to best engineering practices and standards, including NFPA Standards, International Energy Conservation Code, ASHRAE Standards, Clean Water Act, Backflow Prevention Codes, etc. Complying with these norms for designing and installation can be overwhelming, particularly for sizeable projects. And since both systems invite innumerable components and complex design requirements, the possibility of successful installation is far-fetched. That’s where BIM MEP Services come into play. From rendering detailed schematics to overcoming reworks and conflicts, BIM MEP Services can uncomplicate the intricate world of these systems through an advanced technological approach. Let’s see how BIM MEP Services can dramatically improve the way these systems are managed and installed.

Significance of Plumbing and HVAC Systems in the Construction Landscape

A Plumbing System

A plumbing system ensures efficient drainage of wastewater and potable water supply. From piping diameter to borewell and connection to sewage, extensive plumbing solutions span various facets and components. Keeping these components aligned with underlying standards is also paramount to boosting the overall reliability and lifespan of the system. Depending on the project’s region, consideration of the following standards is vital to bringing a plumbing assignment to life.

| Category | Purpose | Examples |

| Building Codes | Regulate various aspects of plumbing design and installation | – International Plumbing Code i.e. IPC: A diverse standard that governs diverse plumbing components, like piping, fixtures, and materials.- Uniform Plumbing Code i.e. UPC: Used where IPC is not applicable |

| Health and Safety Standards | Widely used to reinforce clean water supply and apt waste management | – NSF Standards (aka National Sanitation Foundation): A standard designed to comprehensively regulate potable water materials and systems, ensuring clean water for consumption.- Backflow Prevention Codes: Standards for keeping water hygiene intact during supply by the use of various devices. |

| Accessibility Requirements | Mandate the use of certain plumbing fixtures usable by physically challenged people | – ADA Standards (Americans with Disabilities Act) |

| Water Conservation Standards | Advocate the wise use of potable water | – WaterSense Program: EPA initiative for water-efficient fixtures.- Local mandates for low-flow toilets and faucets. |

| Environmental Standards | Deals with waste disposal and stormwater management | – Clean Water Act (CWA): Enacted to keep water bodies safe from harmful discharge. |

A plumbing system is highly vulnerable to design flaws and installation errors. Managing these via traditional methods can be taxing. This is where MEP BIM Services come into play. You can team up with a reliable partner like J&F for exquisite services, as they are the most experienced contenders in the BIM landscape. By offering advanced and tailored services, J&F yields precise solutions to complex project requirements with steadfast support from start to finish.

HVAC System (H3)

The HVAC system comprises various components such as ducts, air handlers, filters, dampers, grills, thermostats, sensors, heat exchangers, and cooling coils, all contributing to clean air circulation and temperature control. When installing, the following standards or codes come into play.

Adherence to these requires a professional approach and in-depth field acumen. A trusted firm like J&F is well-known for rendering cutting-edge BIM solutions for HVAC endeavours, tailored to address specific project needs. Anyway, let’s focus on the standards governing the HVAC activities.

| Category | Code Type | Purpose | Examples |

| HVAC Codes and Standards | Building Codes | Govern overall construction, including HVAC installation. | – International Building Code (aka IBC): General construction norms, including HVAC integration.ASHRAE Standards:- Standard 90.1: Helps employ measures that promote improved energy efficiency for commercial buildings.- Standard 62.1: Define what should be the various aspects of the ventilation system for elevating improved indoor air quality.- Standard 55: Governs what should be the environmental conditions for ensuring human comfort. |

| Energy Codes | Enacted to keep energy consumption as low as possible, reducing environmental impact. | – International Energy Conservation Code (IECC): Widely used standard for elevating energy efficiency of various establishments. – Energy Star certification: Governs how different electrical equipment should be manufactured, with an end goal to save as much energy as possible without hindering quality. | |

| Environmental Standards | Deals with refrigerants and emissions. | – EPA Section 608 regulates how refrigerants should be handled during various activities, ensuring zero ozone depletion. | |

| Safety Standards | Prevent various mishaps like fires or gas leaks. | – NFPA Standards (National Fire Protection Association): Fosters a long list of guidelines that promote fire protection and ensure systems’ safety.- NFPA 90A: Norms for ACs and ventilation systems used in large buildings. |

How do MEP BIM Services Transform the HVAC and Plumbing Landscape?

To understand why MEP BIM Services are groundbreaking, let’s understand how they resolve the potential bottlenecks of a plumbing and HVAC system.

| Plumbing Bottlenecks | Description | How BIM MEP Services Resolve It |

| Clash Detection | Conflicts between plumbing systems and other building systems such as HVAC, electrical, etc. | Identify loopholes and conflicts via 3D model and resolve them before project initiation, ensuring considerable cost savings and mitigating delays. |

| Inaccurate Sizing of Pipes | Incorrect pipe dimensions lead to problems like varied pressure and flow inefficiency. | MEP BIM Services leverages advanced simulation 3D tools to ensure ultra-precise pipe sizing. |

| Limited Space for Installation | Team stumbling upon tight spaces during installation of plumbing components | Leveraging 3D visualisation and space analysis in the design stage to reinforce explicit system routing, enabling seamless installation regardless of space constraints. |

| Compromised Coordination Among Disciplines | Lack of coordination among key stakeholders such as plumbers, architecture, etc. due to poorly defined workflow | MEP BIM model clubs all the activities and organizes them based on priority, ensuring seamless centralized control. |

| Drainage Slope Issues | Incorrect slope design leads to severe problems such as compromised drainage or blockages. | MEP BIM Services takes advantage of automated calculations and in-depth visual simulation to create an ultra-precise slope design. |

| Material and Component Mismanagement | Derailed supply chain leading to compromised material selection and incorrect quantity estimation. | Experience pinpoint material takeoffs and hassle-free material supply chain via an extensive BIM database. |

| Accessibility for Maintenance | Poor access to valves, cleanouts, and fixtures, leading to derailed maintenance. | BIM tools harmonize maintenance access points within the purview of available spaces, ensuring seamless entry and exit for maintenance professionals |

| Regulatory Non-Compliance | Non-compliant plumbing system resulting in several problems including poorly executed back-flow prevention, water accumulation, leakages, etc. | BIM tools leverage onboard regulatory codes while crafting plumbing design and installation, ensuring zero errors and malfunctions. |

| Inaccurate Cost Estimation | Poorly executed budgeting plan due to lack of key factors, resulting in costly endeavours. | MEP BIM Services use a 5D BIM model integrated with cost data to render pinpoint cost estimation |

| Delay in Project Delivery | Coordination issues and design rework derailed the turnaround time, adding to the client’s woes. | Experience optimized workflow from the ground up with real-time updates spanning every activity. |

Let’s pay attention to HVAC system bottlenecks and what contribution BIM MEP Services can make to alleviate them.

| HVAC Bottlenecks | Description | How MEP BIM Services Resolve It |

| Clash Detection | System faults due to increased conflicts between various components such asHVAC ducts, pipes, and other building systems (plumbing, electrical, etc.). | The advanced 3D models detect clashes in real time and resolve them before kickstarting the installation phase. |

| Improper Duct Sizing | Poorly designed ducts lead to issues like compromised airflow and unbearable noise. | MEP BIM Services uses simulation models to yield ultra-accurate duct size. |

| Limited Space for Ductwork | Tight spaces lead to poor routing, making HVAC installation a challenge for stakeholders. | With 3D visualisation and space analysis, BIM services ensure precise ductwork layout and routing, enabling seamless installation. |

| Poor System Coordination | Miscoodination between HVAC and other systems. | MEP BIM Services brings all stakeholders under one ambit, boosting coordination for improved workflow. |

| Inadequate Ventilation Design | Pooly placed vents and air handlers, leading to compromised indoor air quality and comfort. | BIM-integrated analysis tools make airflow and ventilation as efficient as possible by considering various factors influencing the entire system. |

| Material and Equipment Mismanagement | No clarity on how much material or equipment is to be procured or supplied due to an unclear roadmap. | With the BIM database, the stakeholders can have exceptional control over the material required and procurement, leading to significant time and cost savings. |

| Maintenance Accessibility Issues | Derailed access to filters, fans, or valves due to compromised routing. | BIM tools simulate every component and space, enabling seamless routing in the design phase. |

| Regulatory Non-Compliance | Non-compliance with local energy and ventilation codes, leading to poor performance | BIM models leverage embedded codes to keep design and installation endeavours aligned with underlying norms. |

| Energy Inefficiency | Unplanned design or installation leads to increased power expenses and operational costs. | BIM-integrated energy modelling and simulation keep inefficacies at bay, providing a flawless installtion blueprint. |

| Inaccurate Cost and Time Estimation | Unforeseen design changes or coordination issues lead to compromised budgets and schedules. | 5D and 4D BIM models leverage cost and time data to render pinpoint cost estimation and scheduling. |

Conclusion

The reliability of these systems significantly influences the overall quality of the project. While a thorough plan and traditional practices can pave the foundation for an effective system, what MEP BIM Services can achieve is beyond instrumental. From granular system detail and clash identification to material supply chain, effective MEP BIM service can take the project execution to the next level while having holistic control over potential delays and errors.