Temperature, vibration, pressure, and varied weather conditions significantly impact the structural integrity of any project. Hence, these parameters must be analyzed as profoundly as possible before construction. In the world of structural engineering, finite element analysis methods play an instrumental role in analyzing structural performance against the aforementioned parameters, paving the way for robust construction. Let’s delve deeper into the nitty-gritty of finite element analysis methods and how they impact structural performance.

Understanding the Significance of Finite Element Analysis Methods (FEM)

Structural engineering is a staple to any construction endeavor, detailing the reliability and quality of various components such as a beam, pillars, foundations, trusses, and load-bearing walls. Adding to its strength is the finite element analysis method—a mathematical approach that bifurcates a complex structure into smaller parts, viz., finite elements. These elements are governed by a set of equations based on physical laws.

Structural engineers solve these equations to approximate the behavior of the entire structure. The goal is to analyze how a given structure responds to various parameters such as force, pressure, and displacement, be it dynamic or static. Finite Element Method (FEM) is a go-to method for different engineering applications as it can seamlessly handle complex geometries, materials, and boundary conditions.

Need help analyzing complex structural behavior? Contact our structural analysts today.

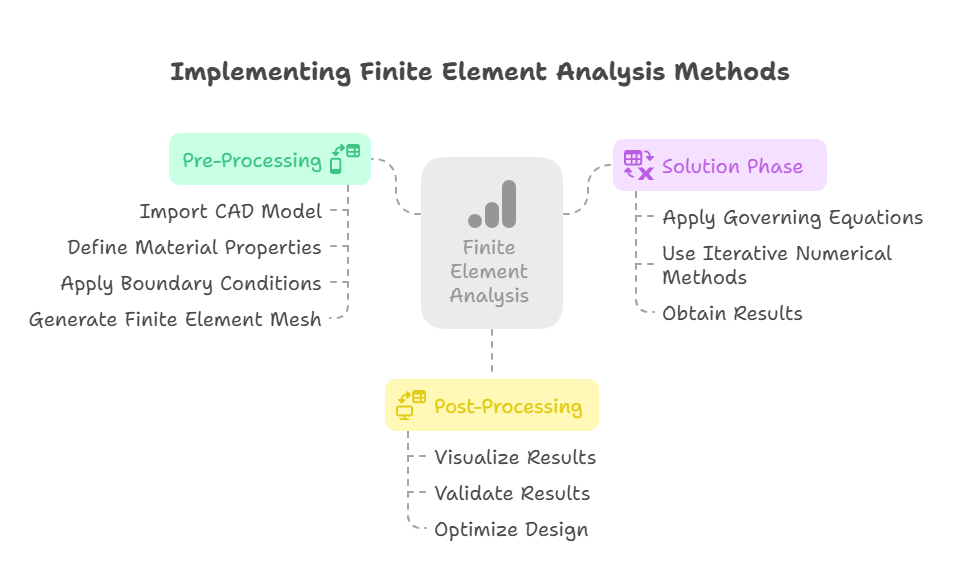

How to Implement Finite Element Analysis Methods in a Project?

There is a systematic approach to unleashing the full potential of FEM. Below are the steps typically used to implement FEM in any structural project:

Step 1: Pre-Processing

Import CAD Model or Create Geometry

The first step includes using the right FEA software to create or import a 3D model of the structure/components. The most common software used for this purpose includes ANSYS, Abaqus, COMSOL, etc.

Define Material Properties

Once the 3D model is imported, the next step involves assigning the material properties such as Young Modulus, Poisson’s Ratio, Density, Thermal conductivity, etc.

Not sure about your material specs? Get a free quote for a detailed FEM consultation.

Apply Boundary Conditions

Applying boundary conditions signifies how the structure reacts to its environment. Following are the boundary conditions extensively used in FEM:

- Fixed Supports (no movement)

- Forces and Loads (gravity, pressure, wind)

- Thermal Conditions (temperature constraints, heat flux)

- Fluid Constraints (inlet velocity, outlet pressure)

- Generate Finite Element Mesh

Model Bifurcation into Small Discrete Element

Once the boundary conditions are defined, the next step involves bifurcating the models into discrete elements for detailed analysis. In general, the following elements come into play while serving such a purpose:

- Tetrahedral Elements (good for complex geometries)

- Hexahedral Elements (better for structured meshing)

Step 2: Solution Phase

Apply Governing Equations

In this step, every discrete element will be subjected to relevant equations based on the type of analysis. Some common equations used in this scenario include:

- Structural: Stress-strain relations (Hooke’s law)

- Thermal: Heat conduction equations

- Fluid Flow: Navier-Stokes equations

- Electromagnetic: Maxwell’s equations

Let us handle the complex calculations for you. Get a free quote from our FEA team.

Use Iterative Numerical Methods

Once you have sorted the relevant equations, it is time to solve them via methods like

- Newton-Raphson Method (for nonlinear problems)

- Gauss-Seidel Method (for iterative solutions)

Obtain Results

Since your goal is to study the structural behavior against varied conditions, seeking the given output becomes paramount.

- Displacement & Deformation (in structures)

- Stress & Strain (for failure analysis)

- Temperature Distribution (for thermal studies)

- Flow Velocity & Pressure Fields (for CFD applications)

Step 3: Post-Processing

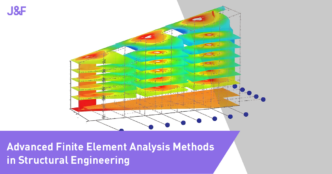

Visualise Results

This step involves visualizing the results by using the following graphical tools:

- Deformations & Stress Distribution (color-coded stress maps)

- Heat Flow & Temperature Gradients (for thermal models)

- Fluid Streamlines & Pressure Contours (for CFD)

Validate Results

Upon meeting the above requirements, it is time to consider experiment data or industry norms to affirm accuracy. Based on the outcome, make relevant changes to material properties, boundary conditions, etc. if required to attain precision.

Optimize Design

Lastly, based on simulation results, optimize the structure to precision. This may involve altering the area, weight, or material. The goal is to make the structure construction-ready.

Also Read: Role of Finite Element Analysis in Enhancing Structural Integrity

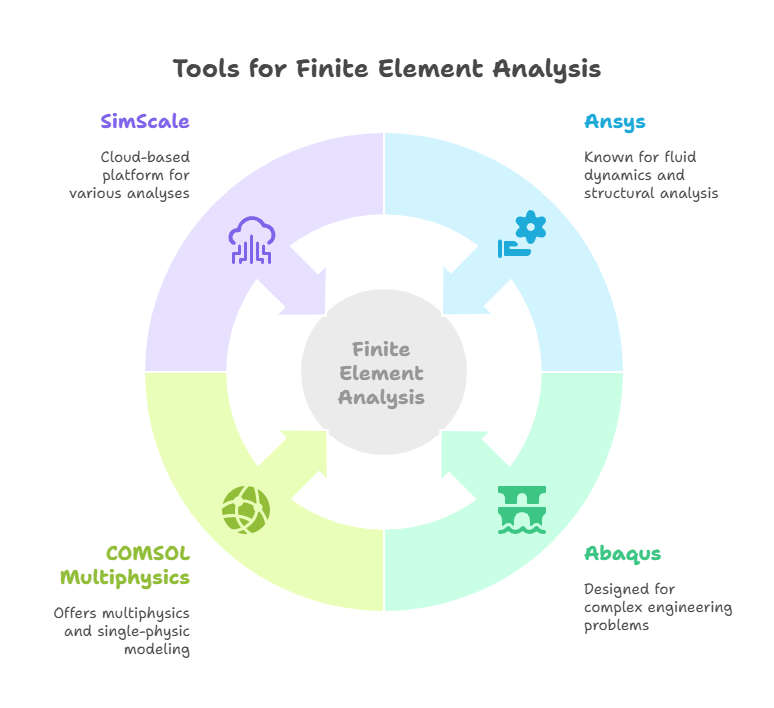

Primary Tools Used for Finite Element Analysis Methods

The following are the tools extensively used to perform finite element analysis:

Ansys

With unparalleled capabilities for fluid dynamics, structural analysis, and thermal simulators, Ansys is a widely used FEM tool that eases the blow for various stakeholders, rendering outputs that matter.

Abaqus

Abaqus is a popular tool designed to cater to complex engineering problems. Designed by Dassault Systèmes, a French-based multinational software corporation, this tool shines with its unparalleled ability to serve various industries.

COMSOL Multiphysics

Being a popular simulation platform, COMSOL Multiphysics software boasts fully coupled multiphysics and single-physic modeling capabilities, making it a go-to tool for simulating designs, devices, and processes in a variety of engineering and manufacturing applications.

SimScale

Powered by the cloud technology, SIMScale is a great addition to the FEM endeavors, allowing a range of analyses, including thermal and computational fluid dynamics (CFD).

Need help selecting the right FEA software for your project? Contact our software experts today!

Conclusion

In the world of structural engineering, things can quickly go awry if due attention is not paid to the structural parts during the design phase. Knowing how different structural elements react to varied load conditions is paramount for robust construction. By using finite element analysis methods, structural engineers can have the leverage to simulate a variety of complex structures to identify potential pitfalls concerning design and reliability.

Planning a project? Get a free quote from our FEM experts and take the guesswork out of design.